Engine Overview:

- Equipped with a BLDC starter, 1x BLDC fuel pump, 1x startup pump, 2x fuel solenoids, and electronic control system (FADEC type).

- Engine may be modified based on customer-specific requirements and operating/installation conditions.

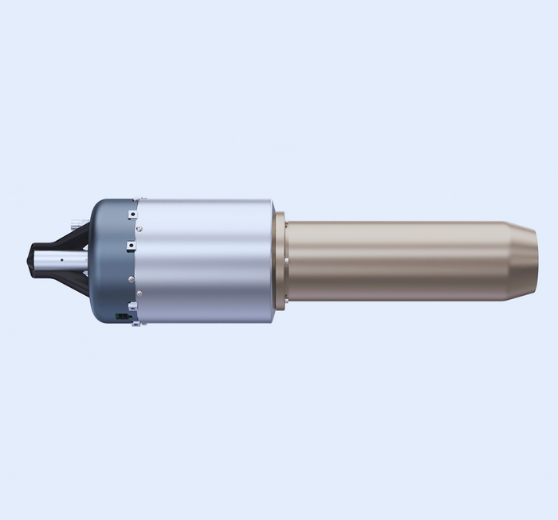

- Available with two different nozzles (long/short).

Functional Description:

The P220-PRO-S2-R1.2 is a single-shaft engine comprising a single-stage radial compressor, annular combustion chamber, single-stage axial turbine, and fixed exhaust nozzle. Intake air is compressed in the radial compressor stage, proceeds through radial and axial diffuser into the combustion chamber where it mixes with vaporized fuel. Combustion gases expand through the axial turbine and exhaust nozzle, generating thrust. The rotor is mounted on 2 ball bearings lubricated by a fuel/oil mix.

Control Options / Electrical Interface:

The JetCat-PRO engine series provides the highest level of integration and maximum ease of installation. All peripheral systems necessary for the engine’s operation are fully integrated below the engine's front cowling.

JetCat P220-PRO Engine Features / Functions:

- ECU (Electronic Control Unit), fully programmable via detachable Ground Support Unit (GSU).

- Brushless starter and seal-free brushless fuel pump.

- Fuel & Kerosene-start solenoids.

- Post fuel filter downstream of the pump (last-barrier filter).

- Barometric altitude/pressure sensor for automatic engine tuning based on operating altitude.

- 4-pin Molex expansion connector (e.g., smoke pumps, fuel transfer pumps, GSU).

- Optional bleed-air port for fuel system pressurization.

- Direct quick start on kerosene via integrated high-speed / low-current ignition system.

- High altitude, high flight speed in-air restart capability.

- Automatic engine cool-down cycle after shutdown.

- Reporting of fuel consumed, fuel flow rate, fuel burned, and remaining fuel in tank.

- Engine/ECU power On/Off via voltage control signal; no external power switches required.

- Engine safety shutdown input for instant shutdown via flight termination system (kills fuel pump, closes safety solenoid valves, stops engine while ECU remains powered for data reporting and cooldown).

- Monitoring and reporting of all currents/voltages and vital engine life parameters/setpoints.

- Automatic fuel purge feature; purging stops automatically when fuel reaches engine.

- High-performance ceramic bearings for durability and smooth operation.

Applications:

- Propulsion of small radio-controlled model aircraft (ideally up to 25kg takeoff mass).

- UAVs.

Notes / Options:

- Engine available in different setups to meet specific installation conditions.

- Different nozzle lengths (currently 3 types) to simplify integration; latest types also include 4x90° radial mounting features.

- Different fuel inlet ports available (Festo or Swagelock fittings).